The importance of the manufacturing industry cannot be ignored in any economy. Innovation and development in the industry are key to driving high-quality economic growth.

A key finding of Huawei’s Global Connectivity Index (GCI )2020 is that the digital transformation of industries will help countries increase productivity, spur economic recovery, and develop future competitiveness. GCI research has suggested that economies that could increase productivity and go digital with intelligent connectivity generally enjoy higher gross value added (GVA) per worker or per hour worked.

The traditional hard-wired networks are fast being replaced with cellular networks to support use cases such as real-time automation, monitoring, tracking, and connected vehicles in various industries.

In the telecommunication manufacturing world, the digital transformation with the fast adoption of 5G network capabilities is expected to generate a profitable market for the network, infrastructure, and equipment vendors with worldwide 5G network infrastructure revenues of $4.2 billion in 2020, amounting to year-over-year growth of 89 percent.

With the growth of technologies such as IoT, the 5G benefits of speed, density, and ultra-low latency combined with the flexibility of private cellular networks, the manufacturing industry can drive innovation with far greater levels of digitization and guaranteed return on investment.

What is a PCN?

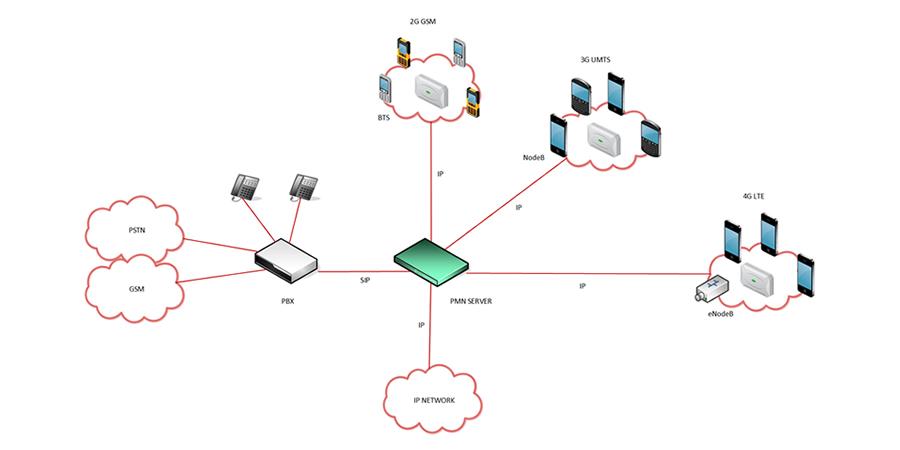

A private cellular or mobile network (PCN) is a local area network (LAN) that uses mobile phone technologies to create a dedicated network with unified connectivity, optimized services, and a secure means of communication within a specific geographic area. It uses LTE or 5G technology used by the public mobile operators but scaled down to provide a wireless network within the premises of the enterprise.

Benefits of PCN

Enterprises are in two minds on whether to use conventional wireless broadband connectivity such as Wi-Fi or public cellular networks as they lack the efficiency, control, and security needed by their business operations. However, private LTE and 5G networks allow for customer-specific mobile networks solutions that can be used in new and challenging applications. Here is the list of benefits of PCNs.

Spectrum availability: Private LTE/5G spectrum is clean and ensures no competing network traffic, facilitating solid reliability as opposed to an unlicensed spectrum.

Broader coverage: PCN provides expansive coverage with fewer access points to create an efficient wireless local network in a large area such as warehouses and distribution centers.

Stable handover: PCNs offer a reliable handover process and keep the calls and data sessions connected even if a user moves from one cell site to another. It can support combinations of low-band, mid-band, and high-band in one network to address the diverse use cases that industries need.

Inherently secure: SIM-based authentication (instead of password protection in Wi-Fi systems)

of cellular networks offers the protection, visibility, and network control to keep businesses safe from data hacks.

Flexibility: Private cellular networks can be managed by the organizations or can be bought as a managed service from a cellular service provider/MVNO. This flexibility will ensure better control and management of connectivity with reliability, resiliency, and predictability. It enables the ability to prioritize performance for some network traffic with quality of service (QoS) settings.

Controlled latency: Enables near real-time communication between thousands of IoT devices, a vital factor in applications such as public safety or robotic movements.

Network slicing: This allows the network to be optimized for the needs of specific user groups, devices or applications over the same infrastructure.

With stable and reliable connectivity of 5G private cellular networks, IoT technology can transform the manufacturing industry. From asset tracking to remote monitoring, from fleet management to environmental measurement, it is increasing control and reducing costs.

Areas were PCN can make a difference in manufacturing

Mobile asset tracking: Whether in manufacturing or any other relevant industry, efficient tracking of valuable mobile assets such as machinery, pallets, and containers is important for the profitability of the organization. Private networks can add value with on-premise standalone networks or ‘hybrid’ models shared with public networks by taking care of the security or data privacy requirements.

Mobile asset tracking service automates visibility of asset distribution and allows for multiple geofences that prompt alerts and monitor asset movement.

Mobile robots and automated guided vehicles (AGVs) require low latency (<10ms) over a broad area to function optimally. Unreliable connectivity and increased latency can stall AGVs and halt production. Contrastingly, 5G private cellular connectivity will ensure that the manufacturing floor is active and running.

Real-time automation: With automation taking over every operation function, a lot of machinery used in manufacturing can be remotely controlled. This will not only decrease downtime, but it will also ensure workers' safety as they can remain out of dangerous conditions during work too. As highlighted by Covid-19 situation, working in close proximity will be discouraged in organizations and investments are likely to go for remote operations centers and supporting technology to enable collaborative work, using video streaming for real-time sharing and augmented reality (AR) to interpret the surrounding environment and equipment.

With such cutting-edge solutions on the rise, manufacturing organizations can achieve increased productivity and efficiency to keep up with the competitiveness and customer demand of their customers.

With the cost and complexity of LTE networks going down, the likelihood of using private networks to deliver real benefits to enterprises is quite clear.

The market for private mobile networks is still in the nascent phase. Industries have new capabilities to transform their operations, promote safety and provide new innovative products and solutions. The new use cases drive the need for more reliable, higher performance wireless solutions offered by the new generation of 4G and 5G private mobile networks.

Telecom operators, network vendors, and system integrators have immense opportunity to jointly create a well-functioning ecosystem that can provide solutions on a case by case basis to meet the needs of the new industrial and enterprise customers.